The Essential Guide to the Parts of Cylinder Head

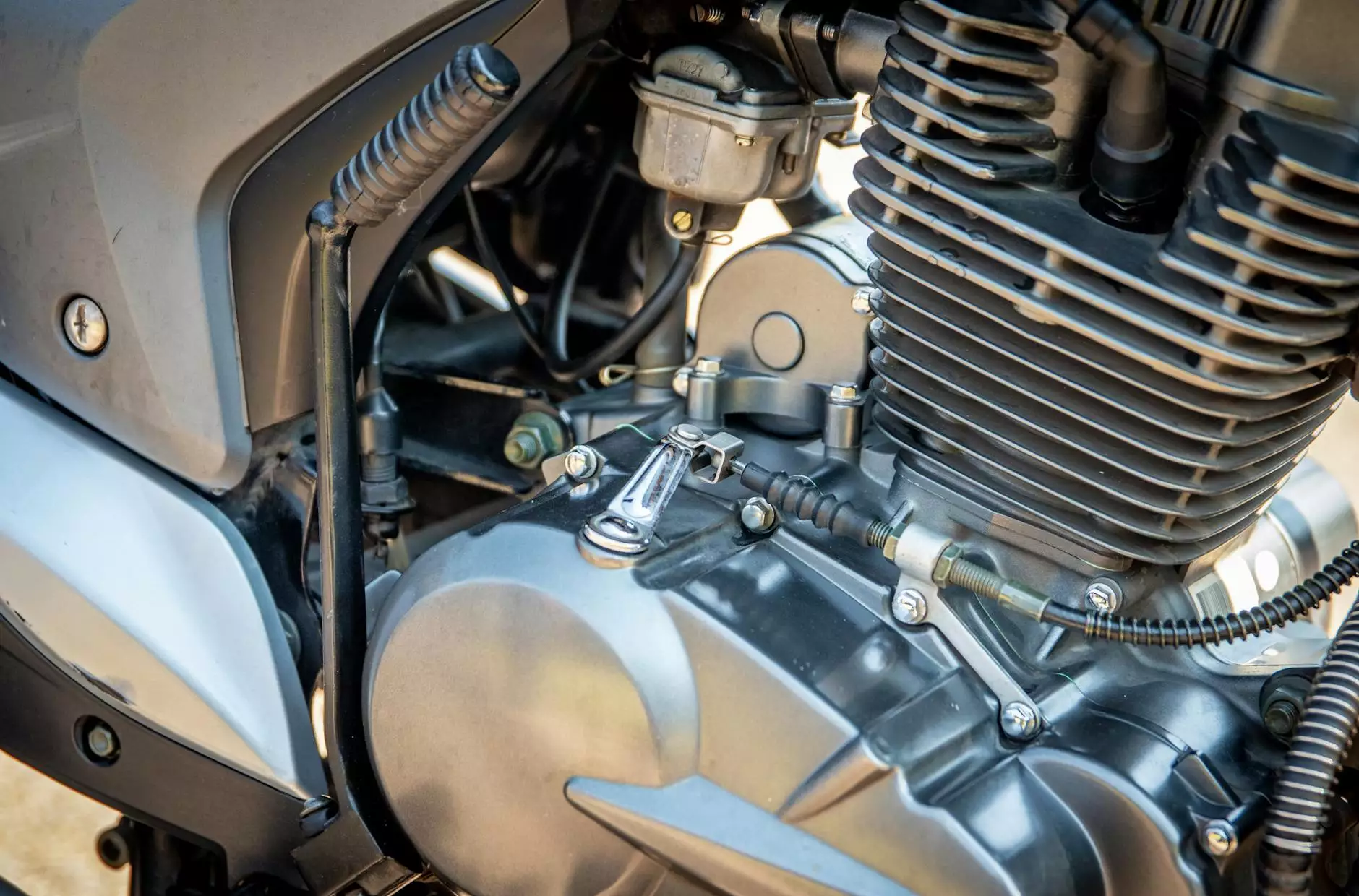

The cylinder head is an integral component of an internal combustion engine, playing a vital role in the overall performance and efficiency of the engine. Understanding the various parts of the cylinder head can provide insights into how your diesel engine functions, the importance of maintaining it, and when to consider replacement or upgrades.

What is a Cylinder Head?

The cylinder head is a critical part of an engine that sits atop the engine block. It seals the combustion chamber and houses important components such as valves, spark plugs, and fuel injectors in diesel engines. The cylinder head ensures that the combustion process can occur efficiently and is crucial in managing the engine's performance, emissions, and fuel efficiency.

Key Parts of the Cylinder Head

Understanding the major parts of the cylinder head is essential for anyone involved in diesel engine maintenance or repair. Below, we break down the key components of a cylinder head:

1. Valves

The valves are one of the most critical parts found in the cylinder head. They control the flow of air and fuel into the combustion chamber and the exhaust gases out of it. There are two main types of valves in most diesel engines:

- Intake Valves: Allow air into the combustion chamber.

- Exhaust Valves: Allow exhaust gases to exit the combustion chamber.

Valves must be precisely timed to ensure optimal combustion, which is managed by the engine's timing system.

2. Valve Springs

The valve springs are crucial for the operation of the valves. They return the valves to their closed position after they have been opened by the camshaft. Strong, durable valve springs are necessary to prevent valve float at high RPMs, which can lead to poor engine performance and potential damage.

3. Rocker Arms

Connecting the camshaft to the valves, rocker arms pivot to open and close the valves at the appropriate time during the engine cycle. Proper functioning of the rocker arms is crucial for maintaining the timing and efficiency of the engine's combustion process.

4. Camshaft

The camshaft is responsible for controlling the timing of the opening and closing of the valves. It plays a pivotal role in engine performance, and any defects can have significant consequences on the engine's efficiency and power output.

5. Cylinder Head Gasket

The cylinder head gasket serves as a seal between the engine block and the cylinder head. This gasket is vital in preventing oil and coolant from leaking and ensuring optimal compression within the combustion chamber. Regular inspections help prevent gasket failure, which can lead to severe engine damage.

6. Combustion Chamber

The combustion chamber is where the fuel-air mixture is ignited. The design and size of this chamber significantly affect the engine's efficiency and power. Different engines may have varying shapes and sizes of combustion chambers, which contribute to their operational characteristics.

7. Plug Holes

In diesel engines, plug holes accommodate fuel injectors, which spray fuel directly into the combustion chamber. The efficiency and timing of fuel injection are crucial for optimal engine performance, minimizing emissions, and maximizing fuel efficiency.

8. Cooling Passages

The cooling passages in a cylinder head play a crucial role in regulating the engine's temperature. Excessive heat can damage engine components, thus these passages direct coolant to absorb heat. Over time, it is essential to maintain these passages to prevent overheating and associated damage.

Importance of Cylinder Head Maintenance

Regular maintenance of the cylinder head and its parts is crucial for ensuring the longevity of your diesel engine. Neglecting components can lead to significant issues, including engine overheating, poor fuel efficiency, and catastrophic failures. Here are key maintenance tips:

- Regular Inspections: Routine checks can help identify wear and tear before they become significant issues.

- Timely Replacements: Parts such as the head gasket and valves should be replaced as per the maintenance schedule.

- Proper Lubrication: Ensure that the moving parts, including the rocker arms and valve springs, are adequately lubricated.

- Regular Cleaning: Clean the cooling passages and combustion chamber to prevent deposits that can hamper performance.

Choosing the Right Parts of Cylinder Head

When it comes to replacing or upgrading any of the parts of the cylinder head, it is essential to choose high-quality components that meet or exceed OEM specifications. Here are some tips for sourcing quality parts:

- Research Suppliers: Look for reputable spare parts suppliers known for providing quality diesel engine parts.

- Quality Assurance: Ensure the parts come with a warranty or guarantee, indicating confidence in their durability and performance.

- Compatibility: Verify that the parts you are purchasing are compatible with your specific engine model.

- Customer Reviews: Read reviews and feedback from other customers who have purchased similar components.

Common Problems Related to Cylinder Heads

Despite proper maintenance, issues can still arise with the cylinder head or its parts. Here are some common problems:

- Cracking: Heat and pressure can cause cracks, which can lead to coolant leaks and overheating.

- Warping: Overheating can cause the cylinder head to warp, creating gaps and leading to a loss of compression.

- Leaking Gaskets: A worn or damaged gasket can lead to leaks of oil and coolant, impacting engine performance.

- Valve Failure: Worn out or damaged valves can lead to poor performance and increased emissions.

Conclusion

Understanding the parts of the cylinder head is vital for any diesel engine owner or enthusiast. This knowledge not only aids in effective maintenance and timely repairs but also enhances your appreciation of how your engine operates. From the valves to the cylinder head gasket, every component plays a significant role in the performance of your diesel engine.

When it comes time to replace parts of your cylinder head, make sure to source high-quality components from reliable suppliers like client-diesel.com. With proper care and attention, you can ensure that your engine runs smoothly and efficiently for years to come.