The Importance of Cylinder Liner Factories in Diesel Engine Manufacturing

In the realm of diesel engine parts, few components are as critical as the cylinder liner. A cylinder liner factory, such as client-diesel.com, plays a pivotal role in ensuring that these engine parts are produced with precision and quality. This article delves deep into the significance of cylinder liners, the manufacturing processes involved, and the integral role that cylinder liner factories play in the engine manufacturing ecosystem.

What is a Cylinder Liner?

A cylinder liner is a vital component of a diesel engine that serves as a sleeve for the pistons to move within. It helps enhance the durability and performance of the engine. The primary functions of a cylinder liner include:

- Providing a smooth surface for the pistons, which helps reduce friction.

- Withstanding high temperatures and pressures during combustion.

- Enhancing the efficiency of the combustion process by maintaining the shape of the combustion chamber.

The Manufacturing Process of Cylinder Liners

The path from raw materials to finished cylinder liners involves several meticulous steps. Understanding this process not only provides insight into the operations of a cylinder liner factory but also highlights the technological advancements in modern manufacturing. Here are the key stages:

1. Material Selection

The first step in producing cylinder liners is selecting the appropriate materials. Typically, high-quality cast iron is chosen due to its excellent wear resistance and ability to withstand high temperatures. Many factories now use advanced alloys to enhance performance further.

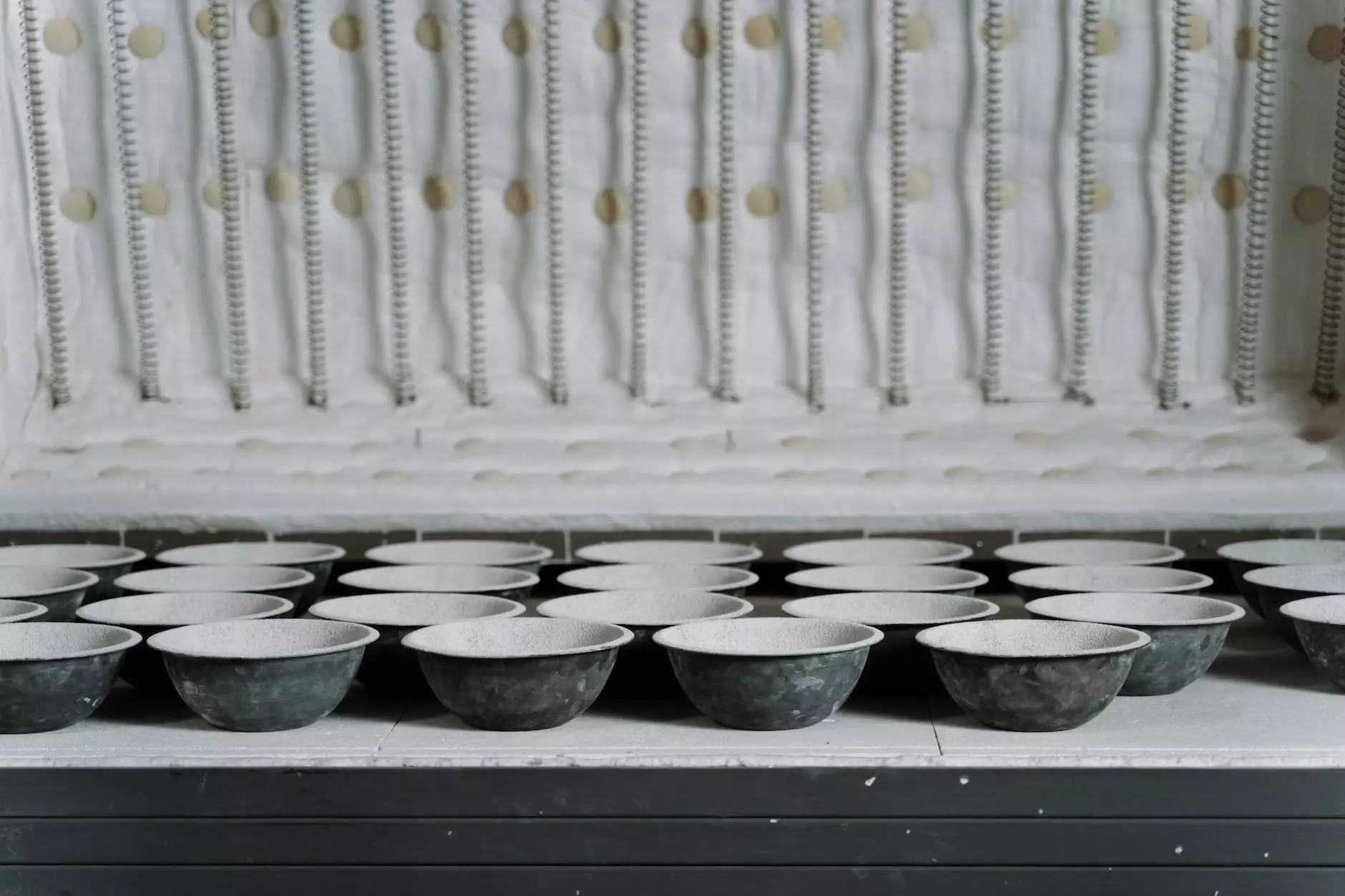

2. Casting

Once the materials are selected, the next process involves casting. This can be done through various methods, including:

- Sand Casting

- Die Casting

- Lost Foam Casting

3. Machining

After casting, the cylinder liners undergo extensive machining. This process includes:

- Turning the liners to achieve precise dimensions.

- Drilling and milling for accuracy in placements.

- Finishing processes to provide a smooth surface that minimizes friction.

4. Heat Treatment

To improve the material properties, cylinder liners often undergo heat treatment. This process helps to increase hardness, reduce brittleness, and improve overall performance under pressure.

5. Quality Control

Quality assurance is paramount in the production of cylinder liners. Every batch must be meticulously tested for:

- Dimensional accuracy

- Material integrity

- Surface finish

The Role of a Cylinder Liner Factory

Cylinder liner factories are crucial to the entire manufacturing process of diesel engines. They are equipped with state-of-the-art technology and highly skilled personnel dedicated to achieving excellence in every produced liner. Some important roles of these factories include:

1. Innovation and R&D

A leading cylinder liner factory invests significantly in research and development to pioneer innovations that drive down emissions, improve fuel efficiency, and extend engine life. Innovations may include enhanced coatings or new alloys that provide better thermal management.

2. Customization

Understanding that generic solutions do not fit all applications, cylinder liner factories offer tailored solutions to meet the unique needs of different engines and manufacturers. This customization may involve varying dimensions, coatings, or materials to suit specific engine performance requirements.

3. Supply Chain Optimization

To meet market demands efficiently, cylinder liner factories strategically manage their supply chains. This allows them to maintain a steady flow of production while minimizing costs. Timely procurement of raw materials and effective logistics strategies enable consistent delivery of high-quality products.

4. Environmental Responsibility

Modern cylinder liner factories are increasingly adopting sustainable practices. This includes recycling waste materials, reducing emissions, and employing energy-efficient manufacturing processes. A commitment to sustainability not only benefits the environment but also enhances company reputation and trust.

The Significance of Cylinder Liners in Diesel Engines

The functionality and durability of diesel engines greatly depend on the quality of their cylinder liners. The characteristics of a well-manufactured cylinder liner include:

- High wear resistance to extend engine life.

- Optimal thermal conductivity for effective heat dissipation.

- Corrosion resistance to withstand harsh operating conditions.

By investing in high-quality cylinder liners, manufacturers can enhance the performance and reliability of their diesel engines, offering customers unprecedented longevity and efficiency.

Challenges Faced by Cylinder Liner Factories

Despite their technological advancements, cylinder liner factories encounter several challenges:

1. Competition

The industry is facing stiff competition from both local and international players. To remain competitive, factories must continually innovate and improve their production processes.

2. Supply Chain Disruptions

Global events, such as pandemics or geopolitical issues, can disrupt the supply chains for raw materials, affecting production schedules.

3. Regulatory Compliance

Increasingly stringent regulations regarding emissions and environmental impact require factories to adapt quickly, often necessitating upgrades to machinery and processes.

Looking to the Future: Innovations in Cylinder Liner Production

The future of cylinder liner factories looks bright, particularly with the advent of new technologies. Some key trends include:

- Advancements in Additive Manufacturing: This technology allows for intricate designs and can reduce waste during production.

- Smart Manufacturing Technologies: The integration of IoT sensors and AI can optimize production processes, improving efficiency and quality.

- Focus on Sustainable Materials: Developing eco-friendly materials that do not compromise performance will be critical as environmental concerns grow.

Conclusion

The role of a cylinder liner factory in the manufacturing of diesel engine parts cannot be overstated. It is an industry marked by innovation, precision, and a commitment to quality. As technology advances, these factories will continue to evolve, providing the essential components that fuel the performance and durability of diesel engines. Companies like client-diesel.com are at the forefront of this evolution, ensuring that they remain leaders in the production of quality diesel engine parts.