Unlocking the Power of Rotary Lobe Blower Technology in Modern Business

In the rapidly evolving landscape of industrial and commercial operations, rotary lobe blowers have emerged as a cornerstone technology that drives efficiency, sustainability, and profitability. As a highly reliable and versatile form of positive displacement blowers, these machines are transforming sectors ranging from wastewater treatment to food processing, aeration, pneumatic conveying, and beyond. This article delves deep into the realm of rotary lobe blower technology, elucidating its mechanisms, multitude of benefits, and strategic applications that can propel your business ahead of the competition.

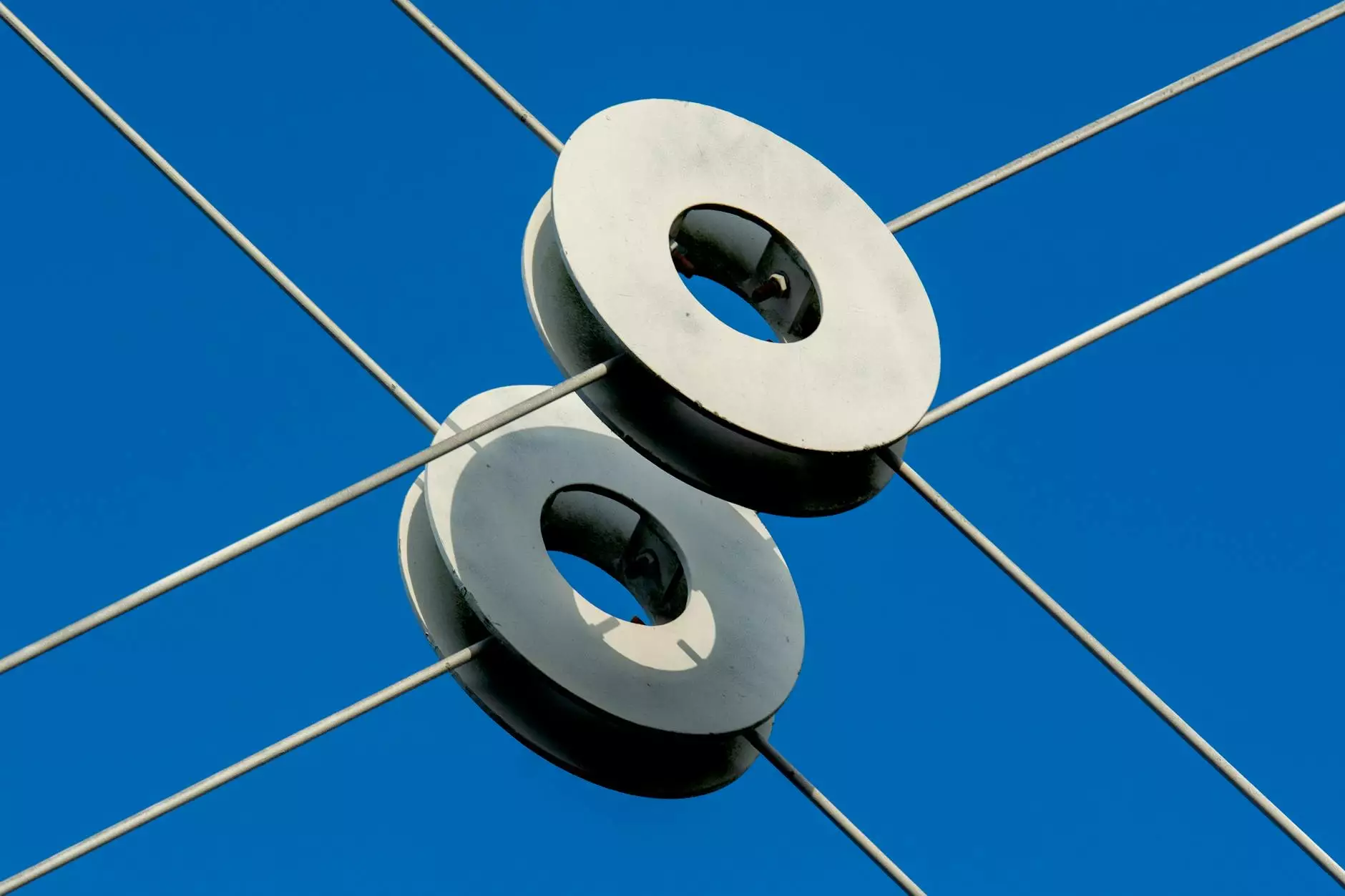

What is a Rotary Lobe Blower? An Overview of its Engineering Foundations

A rotary lobe blower is a type of positive displacement blower that utilizes rotors with lobes, which intermesh within a casing to trap and move air or gases from the inlet to the outlet. Unlike centrifugal blowers that rely on centrifugal force, rotary lobe blowers mechanically displace air, ensuring a steady, pulsation-free flow at relatively low speeds.

Core components include:

- Rotors with lobes designed to mesh closely but without contact, ensuring minimal wear and high energy efficiency.

- Casing that houses the rotors and maintains a sealed environment for optimum operation.

- Lubrication system to reduce friction and extend component life.

- Inlet and outlet ports for air intake and discharge, respectively.

These blowers typically operate under a vacuum or positive pressure, depending on specific industrial needs, making them a flexible solution for various applications.

Advantages of Using Rotary Lobe Blowers in Business Operations

1. Superior Efficiency and Reliability

One of the standout features of rotary lobe blowers is their ability to deliver consistent airflow with minimal pulsation. Their robust construction and simple design translate into high operational reliability and low maintenance requirements. This results in reduced downtime and lower operational costs, fostering seamless business continuity.

2. Energy Conservation and Cost-Effectiveness

Compared to other types of blowers, rotary lobe models are known for their energy efficiency, especially when matched correctly to application needs. By optimizing airflow and minimizing power consumption, companies can significantly reduce their carbon footprint and operational expenses.

3. Versatility Across Industries

The adaptability of rotary lobe blowers makes them suitable for a wide array of sectors, including:

- Wastewater Treatment: Aeration processes critical for biological treatment and oxygen transfer.

- Food and Beverage: Gentle handling of powders, grains, and other sensitive materials.

- Textile Industry: Air agitation and material conveying.

- Chemical Processing: Handling of corrosive gases with appropriate materials.

- Pneumatic Conveying: Moving bulk powders without product degradation.

4. Reduced Noise Levels

The design of rotary lobes ensures quieter operation compared to other blower types. This contributes to a more comfortable workspace and less environmental noise pollution, aligning with modern industrial sustainability goals.

5. Ease of Maintenance and Longevity

Thanks to their straightforward design, rotary lobe blowers are easier to maintain. Regular inspections, lubrication, and rotor clearances are sufficient to keep machines running at peak performance, often exceeding 20,000 operating hours before significant overhauls are necessary.

Deep Dive: How a Rotary Lobe Blower Works

The operation of a rotary lobe blower hinges on positive displacement. It utilizes two or more rotors with lobes that rotate in opposite directions within a casing. The process involves several stages:

- Inlet phase: Air enters through the inlet port and fills the space between the lobes and the casing.

- Displacement phase: As the rotors turn, they trap a volume of air and carry it around the casing, reducing the volume of air in the cavity.

- Compression and discharge: The trapped air is moved to the outlet side, where it is expelled at a high velocity and pressure.

This constant process results in a continuous, pulsation-free airflow suitable for delicate and precise industrial applications.

Strategic Applications of Rotary Lobe Blower Technology

1. Wastewater Treatment Plants

In wastewater management, rotary lobe blowers provide vital aeration, enhancing aerobic bacteria activity essential for breaking down organic pollutants. Their ability to operate under varying load conditions makes them an indispensable part of effective treatment cycles.

2. Commercial and Industrial Manufacturing

Their capacity to handle delicate materials and generate consistent airflow supports manufacturing processes such as pneumatic conveying, drying, and aeration in food, pharmaceutical, and chemical industries.

3. Environmental Sustainability Initiatives

Rotary lobe blowers are favored in green initiatives due to their energy efficiency and low noise emissions. They support efforts such as emission control, renewable energy projects, and pollution mitigation.

4. Special Chemical Handling

The ability to customize materials and coatings of lobes and casings makes rotary lobe blowers suitable for handling corrosive or hazardous gases safely and effectively.

How to Optimize Rotary Lobe Blower Performance for Your Business

- Proper Sizing: Select a blower with the appropriate capacity and pressure specifications to match your process demands, avoiding over or under-sizing issues.

- Regular Maintenance: Implement a routine maintenance schedule, including rotor clearances, lubrication checks, and part replacements to ensure longevity.

- Material Selection: Choose suitable materials for lobes and casing based on corrosiveness, abrasiveness, and temperature requirements.

- Operational Monitoring: Use advanced sensors and control systems to monitor operational parameters, optimize energy consumption, and preempt failures.

The Future of Rotary Lobe Blower Technology in Industry

As industries strive toward sustainability and operational excellence, rotary lobe blowers are poised to experience continued innovation. Developments in smart technology integration, variable speed drives, and eco-friendly materials will further enhance their efficiency and adaptability.

Furthermore, advancements in noise reduction, energy recovery systems, and corrosion-resistant components will expand their applicability in more demanding environments, ensuring they remain a vital component of modern industrial infrastructure.

Partnering with Leading Providers: Why Choose tmm.com.tr

At tmm.com.tr, we specialize in high-quality rotary lobe blowers and comprehensive service solutions tailored to your specific operational needs. Our expert team ensures you acquire the most suitable equipment, backed by after-sales support, maintenance, and upgrades.

- Quality Assurance: We supply only premium-grade, tested rotary lobe blowers that meet international standards.

- Customized Solutions: Our team assesses your process parameters to recommend the optimal blower configuration.

- Technical Support: Ongoing technical consultation, maintenance, and training to maximize equipment performance.

- Competitive Pricing: We provide cost-effective solutions that do not compromise on quality.

In Conclusion: Elevate Your Business with Advanced Rotary Lobe Blower Solutions

Implementing rotary lobe blower technology is more than a strategic decision—it's an investment in operational excellence and environmental responsibility. By understanding their capabilities, benefits, and best practices for application, your business can achieve unparalleled efficiency, sustainability, and competitive advantage.

Partner with trusted industry leaders like tmm.com.tr to harness the full potential of rotary lobe blowers and propel your operations into the future.

Every successful business today depends on innovative, reliable technology solutions. Choose rotary lobe blowers—your gateway to cleaner, faster, and more economical operations.